SDS plus mata bor palu kanthi ujung lurus kanggo beton lan masonry

Fitur

1. SDS Plus Shank: SDS Plus palu pengeboran bit dirancang karo SDS Plus shank specialized, kang nyedhiyani sambungan aman lan dipercaya antarane dicokot lan pengeboran. Desain shank iki ngidini gampang masang lan mbusak bit lan njamin transmisi daya maksimal sajrone pengeboran.

2. Tungsten Carbide Tip: Tip pengeboran biasane digawe saka tungsten carbide, bahan sing kuwat lan awet sing dikenal kanthi resistensi sing apik kanggo nyandhang lan panas. Tip karbida iki dirancang khusus kanggo ngebor bahan sing angel kaya beton lan masonry kanthi efektif, njamin pengeboran sing efisien lan tepat.

3. Desain Suling: SDS Plus palu pengeboran bit duwe desain seruling unik karo grooves helical sing bantuan ing aman cepet saka lebu sak ngebur. Suling uga mbantu nyuda gesekan lan penumpukan panas, sing bisa ngrusak bit utawa alon proses pengeboran.

4. Dikiataken inti: bit pengeboran iki asring fitur inti dikiataken kanggo nambah kekuatan lan kekiatan, utamané nalika ngebur liwat beton hard utawa masonry. Inti sing dikuatake nyegah bit saka mlengkung utawa pecah lan ngidini pengeboran luwih agresif.

5. Kontrol Getaran Optimal: SDS Plus palu pengeboran bit biasane duwe fitur sing mbantu nyuda geter sak ngebur. Iki kalebu desain lan bahan khusus sing nyuda getaran, nyedhiyakake kontrol lan kenyamanan sing luwih apik kanggo pangguna.

6. Wide Range of Sizes: SDS Plus palu pengeboran bit teka ing macem-macem ukuran, kiro-kiro saka sawetara millimeters kanggo sawetara centimeter ing diameteripun. Jangkoan ekstensif iki ngidini pangguna milih ukuran sing pas kanggo aplikasi pengeboran khusus ing beton lan masonry.

7. Kompatibilitas: SDS Plus palu pengeboran bit dirancang khusus kanggo nggunakake SDS Plus Rotary palu pengeboran. Iki njamin kompatibilitas antarane pengeboran lan bit, ngoptimalake kinerja pengeboran lan efisiensi.

Produksi & Workshop

Kaluwihan

1. Dhuwur Kekiatan: SDS Plus palu pengeboran bit dirancang khusus kanggo tahan panjaluk angel pengeboran menyang beton lan masonry. Iki digawe nggunakake bahan berkualitas tinggi kayata tip karbida, sing nyedhiyakake daya tahan sing luar biasa, umur alat sing dawa, lan tahan kanggo nyandhang lan panas.

2. Pengeboran Efisien: Desain khusus pengeboran palu SDS Plus njamin pengeboran efisien ing beton lan masonry. Geometri suling lan alur heliks ing bit mbantu mbusak bledug lan lebu kanthi cepet, saéngga kecepatan pengeboran luwih cepet lan nyegah clogging. Iki, ing siji, ndadékaké kanggo nambah produktivitas lan irit wektu.

3. Transfer Energy Impact Meningkat: SDS Plus desain shank menehi transfer energi impact banget saka pengeboran kanggo dicokot. Shank ngunci menyang chuck pengeboran kanthi aman, ngilangake potensial slip utawa mundhut daya sajrone pengeboran. Iki nyebabake tambah daya pengeboran lan kinerja sing luwih apik, sanajan ing bahan sing atos.

4. Owah-owahan Bit Gampang: SDS Plus palu pengeboran bit ngidini kanggo owah-owahan dicokot cepet lan gampang. Bit duwe grooved utawa slotted shank unik sing mbisakake kanggo dilebokake lan dibusak saka pengeboran tanpa perlu alat tambahan. Iki ngidini kanggo cepet lan trep ngoper antarane ukuran bit beda utawa jinis sak tugas ngebur.

5. Versatility: SDS Plus palu pengeboran bit Highly Versatile lan bisa digunakake kanggo sawetara saka sudhut aplikasi. Padha cocok kanggo ngebur bolongan ambane beda lan diameteripun ing macem-macem lumahing beton lan masonry, kalebu tembok, jubin, lan pondasi. Kajaba iku, sawetara bit SDS Plus duwe fitur kombinasi pengeboran lan pahat, saengga migunani kanggo tugas pengeboran lan pahat ringan.

6. Suda geter lan pangguna lemes: SDS Plus palu pengeboran bit dirancang kanggo nyilikake geter sak ngebur. Iki mbantu nyuda rasa kesel lan rasa ora nyaman pangguna, supaya operator bisa kerja luwih suwe tanpa ngalami ketegangan sing gedhe banget. Tingkat geter sing luwih murah uga nyumbang kanggo akurasi lan presisi sing luwih apik sajrone pengeboran.

7. Pengeboran sing Aman lan Stabil: Mekanisme ngunci SDS Plus shank nyedhiyakake sambungan sing aman antarane bor lan chuck, njamin stabilitas lan nyegah slippage nalika pengeboran torsi dhuwur ing bahan sing angel. Stabilitas iki nambah kontrol lan akurasi, nggawe pengeboran luwih aman lan luwih efisien.

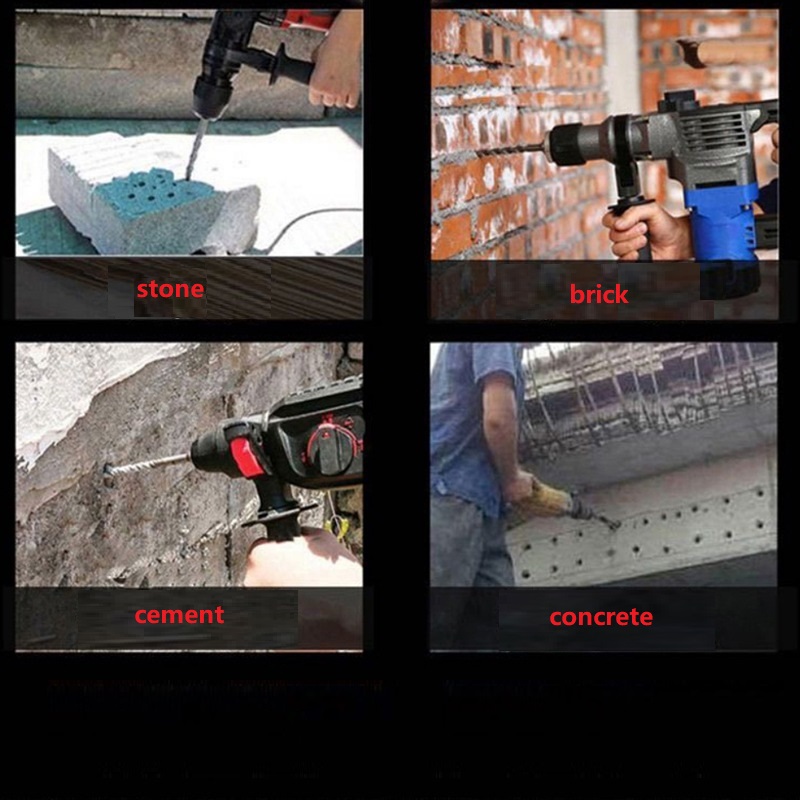

Aplikasi

| Diameter x Panjang Sakabèhé (mm) | dawa kerja (mm) | Diameter x Panjang Sakabèhé (mm) | dawa kerja (mm) |

| 4.0 x 110 | 45 | 14,0 x 160 | 80 |

| 4.0 x 160 | 95 | 14,0 x 200 | 120 |

| 5,0 x 110 | 45 | 14,0 x 260 | 180 |

| 5.0 x 160 | 95 | 14,0 x 300 | 220 |

| 5,0 x 210 | 147 | 14,0 x 460 | 380 |

| 5,0 x 260 | 147 | 14,0 x 600 | 520 |

| 5,0 x 310 | 247 | 14,0 x 1000 | 920 |

| 6,0 x 110 | 45 | 15,0 x 160 | 80 |

| 6,0 x 160 | 97 | 15,0 x 200 | 120 |

| 6,0 x 210 | 147 | 15,0 x 260 | 180 |

| 6,0 x 260 | 197 | 15,0 x 460 | 380 |

| 6,0 x 460 | 397 | 16,0 x 160 | 80 |

| 7,0 x 110 | 45 | 16,0 x 200 | 120 |

| 7,0 x 160 | 97 | 16,0 x 250 | 180 |

| 7,0 x 210 | 147 | 16,0 x 300 | 230 |

| 7,0 x 260 | 147 | 16,0 x 460 | 380 |

| 8.0 x 110 | 45 | 16,0 x 600 | 520 |

| 8.0 x 160 | 97 | 16,0 x 800 | 720 |

| 8,0 x 210 | 147 | 16,0 x 1000 | 920 |

| 8,0 x 260 | 197 | 17,0 x 200 | 120 |

| 8,0 x 310 | 247 | 18,0 x 200 | 120 |

| 8,0 x 460 | 397 | 18,0 x 250 | 175 |

| 8,0 x 610 | 545 | 18,0 x 300 | 220 |

| 9,0 x 160 | 97 | 18,0 x 460 | 380 |

| 9,0 x 210 | 147 | 18,0 x 600 | 520 |

| 10.0 x 110 | 45 | 18,0 x 1000 | 920 |

| 10,0 x 160 | 97 | 19,0 x 200 | 120 |

| 10,0 x 210 | 147 | 19,0 x 460 | 380 |

| 10,0 x 260 | 197 | 20,0 x 200 | 120 |

| 10,0 x 310 | 247 | 20,0 x 300 | 220 |

| 10,0 x 360 | 297 | 20,0 x 460 | 380 |

| 10,0 x 460 | 397 | 20,0 x 600 | 520 |

| 10,0 x 600 | 537 | 20,0 x 1000 | 920 |

| 10,0 x 1000 | 937 | 22,0 x 250 | 175 |

| 11.0 x 160 | 95 | 22,0 x 450 | 370 |

| 11.0 x 210 | 145 | 22,0 x 600 | 520 |

| 11,0 x 260 | 195 | 22,0 x 1000 | 920 |

| 11,0 x 300 | 235 | 24,0 x 250 | 175 |

| 12,0 x 160 | 85 | 24,0 x 450 | 370 |

| 12,0 x 210 | 135 | 25,0 x 250 | 175 |

| 12,0 x 260 | 185 | 25,0 x 450 | 370 |

| 12,0 x 310 | 235 | 25,0 x 600 | 520 |

| 12,0 x 460 | 385 | 25,0 x 1000 | 920 |

| 12,0 x 600 | 525 | 26,0 x 250 | 175 |

| 12,0 x 1000 | 920 | 26,0 x 450 | 370 |

| 13,0 x 160 | 80 | 28,0 x 450 | 370 |

| 13,0 x 210 | 130 | 30,0 x 460 | 380 |

| 13,0 x 260 | 180 | …… | |

| 13,0 x 300 | 220 | ||

| 13,0 x 460 | 380 | 50*1500 |