DIN338 Kanthi Ground HSS M2 Twist Drill Bits

Fitur

Bit bor twist HSS M2 DIN338 kanthi lemah nduweni sawetara fitur sing luar biasa, kalebu:

Bahan Baja Kacepetan Dhuwur (HSS) M2: Panganggone bahan HSS M2 nyedhiyakake kekerasan sing unggul, tahan abrasi, lan tahan panas, nggawe bor iki cocog kanggo ngebor macem-macem bahan, kalebu baja tahan karat, baja paduan, lan bahan non-logam. logam ireng.

FLUTES GROUND FULL AND CUTTING EDGES: Bor iku tliti lemah kanggo nyedhiyani grooves cetha lan konsisten lan nglereni sudhut, asil ing apik evakuasi chip, suda gesekan lan tambah akurasi pengeboran.

Titik pamisah 135 derajat: Bit pengeboran nganggo desain titik pamisah 135 derajat, sing mbantu nyuda kabutuhan bolongan pilot, nambah kemampuan pusat lan fokus, lan nambah efisiensi pengeboran.

GLOSSY FINISH: Rampung sing padhang ing bit pengeboran nolak karat, ningkatake aliran chip, lan nyedhiyakake visibilitas sing luwih apik sajrone operasi, mbantu ningkatake kinerja lan umur layanan.

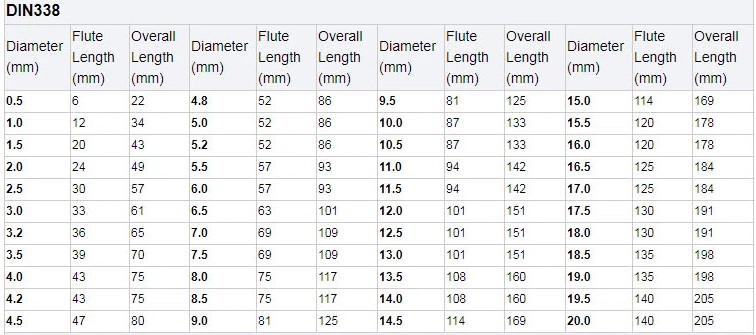

DIN338 Compliant: Latihan tundhuk karo standar DIN338, njamin dimensi konsisten, manufaktur kualitas dhuwur, lan ketemu standar industri kanggo akurasi lan linuwih.

Aplikasi Versatile: Bit pengeboran twist iki cocok kanggo tugas pengeboran umum ing macem-macem bahan, nggawe serbaguna lan praktis kanggo macem-macem aplikasi pengeboran.

Umur alat sing dawa: Kombinasi bahan HSS M2 sing berkualitas tinggi, penggilingan tliti lan desain tahan lama mbantu nambah umur alat lan nyuda frekuensi panggantos lan pangopènan.

Bebarengan, fitur-fitur kasebut nggawe DIN338 kanthi lemah HSS M2 bor twist minangka alat sing dipercaya lan kinerja dhuwur kanggo aplikasi pengeboran profesional lan industri.

PRODUCT show

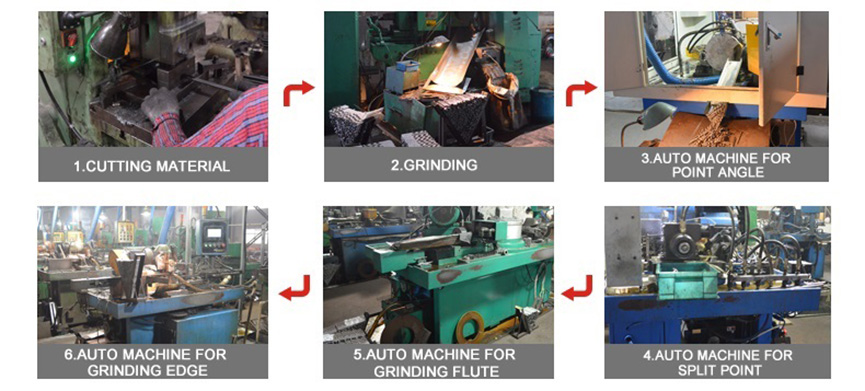

ALIRAN PROSES

Kaluwihan

DIN338 kanthi lemah HSS M2 mata bor twist nawakake macem-macem kaluwihan, kalebu:

Kekiatan Dhuwur: Bahan HSS M2 nyedhiyakake kekerasan sing unggul lan tahan tahan kanggo daya tahan sing tahan suwe, utamane nalika ngebor bahan sing angel kayata stainless steel, baja paduan lan logam non-ferrous.

Presisi lan Akurasi: Seruling lemah lan pinggiran nglereni njamin kinerja pengeboran sing tepat lan konsisten, ngasilake bolongan sing resik lan akurat.

Evakuasi chip efisien: Grooves lemah presisi lan nglereni sudhut nggampangake evakuasi chip efisien, minimalake clogging lan nambah efficiency ngebur.

Kacepetan pengeboran sing tambah: Desain titik pamisah 135 derajat nyuda kabutuhan pra-pengeboran, ngidini pengeboran luwih cepet lan produktivitas tambah.

Nyuda panas lan gesekan: materi baja kacepetan dhuwur lan tliti mecah mbantu nyuda panas mbangun-munggah lan gesekan sak ngebur, asil ing operasi Gamelan lan urip alat maneh.

Resistance Korosi: Lumahing padhang ing bit pengeboran tahan korosi, ndawakake umur bor lan njaga kinerja pemotongan. Versatility: Bit pengeboran iki cocok kanggo macem-macem aplikasi pengeboran, nggawe serbaguna lan praktis kanggo digunakake ing macem-macem bahan lan industri.

Kanthi menehi kaluwihan kasebut, bit bor twist HSS M2 DIN338 kanthi lengkap nyedhiyakake linuwih, efisiensi lan umur dawa ing operasi pengeboran.

| DIN338 HSS TWIST DRILL BIT | ||||||||

| Diameter (mm) | Panjang Flute (mm) | Sakabèhé dawa (mm) | Diameter (mm) | Panjang Flute (mm) | Sakabèhé dawa (mm) | Diameter (mm) | Panjang Flute (mm) | Sakabèhé dawa (mm) |

| 0.2 | 2.5 | 19.0 | 5.6 | 57.0 | 93.0 | 11.0 | 94.0 | 142.0 |

| 0.3 | 3.0 | 19.0 | 5.7 | 57.0 | 93.0 | 11.1 | 94.0 | 142.0 |

| 0.4 | 5.0 | 20.0 | 5.8 | 57.0 | 93.0 | 11.2 | 94.0 | 142.0 |

| 0.5 | 6.0 | 22.0 | 5.9 | 57.0 | 93.0 | 11.3 | 94.0 | 142.0 |

| 0.6 | 7.0 | 24.0 | 6.0 | 57.0 | 93.0 | 11.4 | 94.0 | 142.0 |

| 0.7 | 9.0 | 28.0 | 6.1 | 63.0 | 101.0 | 11.5 | 94.0 | 142.0 |

| 0.8 | 10.0 | 30.0 | 6.2 | 63.0 | 101.0 | 11.6 | 94.0 | 142.0 |

| 0.9 | 11.0 | 32.0 | 6.3 | 63.0 | 101.0 | 11.7 | 94.0 | 142.0 |

| 1.0 | 12.0 | 34.0 | 6.4 | 63.0 | 101.0 | 11.8 | 94.0 | 142.0 |

| 1.1 | 14.0 | 36.0 | 6.5 | 63.0 | 101.0 | 11.9 | 101.0 | 151.0 |

| 1.2 | 16.0 | 38.0 | 6.6 | 63.0 | 101.0 | 12.0 | 101.0 | 151.0 |

| 1.3 | 16.0 | 38.0 | 6.7 | 63.0 | 101.0 | 12.1 | 101.0 | 151.0 |

| 1.4 | 18.0 | 40.0 | 6.8 | 69.0 | 109.0 | 12.2 | 101.0 | 151.0 |

| 1.5 | 18.0 | 40.0 | 6.9 | 69.0 | 109.0 | 12.3 | 101.0 | 151.0 |

| 1.6 | 20.0 | 43.0 | 7.0 | 69.0 | 109.0 | 12.4 | 101.0 | 151.0 |

| 1.7 | 20.0 | 43.0 | 7.1 | 69.0 | 109.0 | 12.5 | 101.0 | 151.0 |

| 1.8 | 22.0 | 46.0 | 7.2 | 69.0 | 109.0 | 12.6 | 101.0 | 151.0 |

| 1.9 | 22.0 | 46.0 | 7.3 | 69.0 | 109.0 | 12.7 | 101.0 | 151.0 |

| 2.0 | 24.0 | 49.0 | 7.4 | 69.0 | 109.0 | 12.8 | 101.0 | 151.0 |

| 2.1 | 24.0 | 49.0 | 7.5 | 69.0 | 109.0 | 12.9 | 101.0 | 151.0 |

| 2.2 | 27.0 | 53.0 | 7.6 | 75.0 | 117.0 | 13.0 | 101.0 | 151.0 |

| 2.3 | 27.0 | 53.0 | 7.7 | 75.0 | 117.0 | 13.1 | 101.0 | 151.0 |

| 2.4 | 30.0 | 57.0 | 7.8 | 75.0 | 117.0 | 13.2 | 101.0 | 151.0 |

| 2.5 | 30.0 | 57.0 | 7.9 | 75.0 | 117.0 | 13.3 | 108.0 | 160.0 |

| 2.6 | 30.0 | 57.0 | 8.0 | 75.0 | 117.0 | 13.4 | 108.0 | 160.0 |

| 2.7 | 33.0 | 61.0 | 8.1 | 75.0 | 117.0 | 13.5 | 108.0 | 160.0 |

| 2.8 | 33.0 | 61.0 | 8.2 | 75.0 | 117.0 | 13.6 | 108.0 | 160.0 |

| 2.9 | 33.0 | 61.0 | 8.3 | 75.0 | 117.0 | 13.7 | 108.0 | 160.0 |

| 3.0 | 33.0 | 61.0 | 8.4 | 75.0 | 117.0 | 13.8 | 108.0 | 160.0 |

| 3.1 | 36.0 | 65.0 | 8.5 | 75.0 | 117.0 | 13.9 | 108.0 | 160.0 |

| 3.2 | 36.0 | 65.0 | 8.6 | 81.0 | 125.0 | 14.0 | 108.0 | 160.0 |

| 3.3 | 36.0 | 65.0 | 8.7 | 81.0 | 125.0 | 14.3 | 114.0 | 169.0 |

| 3.4 | 39.0 | 70.0 | 8.8 | 81.0 | 125.0 | 14.5 | 114.0 | 169.0 |

| 3.5 | 39.0 | 70.0 | 8.9 | 81.0 | 125.0 | 14.8 | 114.0 | 169.0 |

| 3.6 | 39.0 | 70.0 | 9.0 | 81.0 | 125.0 | 15.0 | 114.0 | 169.0 |

| 3.7 | 39.0 | 70.0 | 9.1 | 81.0 | 125.0 | 15.3 | 120.0 | 178.0 |

| 3.8 | 43.0 | 75.0 | 9.2 | 81.0 | 125.0 | 15.5 | 120.0 | 178.0 |

| 3.9 | 43.0 | 75.0 | 9.3 | 81.0 | 125.0 | 15.8 | 120.0 | 178.0 |

| 4.0 | 43.0 | 75.0 | 9.4 | 81.0 | 125.0 | 16.0 | 120.0 | 178.0 |

| 4.1 | 43.0 | 75.0 | 9.5 | 81.0 | 125.0 | 16.3 | 125.0 | 184.0 |

| 4.2 | 43.0 | 75.0 | 9.6 | 87.0 | 133.0 | 16.5 | 125.0 | 184.0 |

| 4.3 | 47.0 | 80.0 | 9.7 | 87.0 | 133.0 | 16.8 | 125.0 | 184.0 |

| 4.4 | 47.0 | 80.0 | 9.8 | 87.0 | 133.0 | 17.0 | 125.0 | 184.0 |

| 4.5 | 47.0 | 80.0 | 9.9 | 87.0 | 133.0 | 17.3 | 130.0 | 191.0 |

| 4.6 | 47.0 | 80.0 | 10.0 | 87.0 | 133.0 | 17.5 | 130.0 | 191.0 |

| 4.7 | 47.0 | 80.0 | 10.1 | 87.0 | 133.0 | 17.8 | 130.0 | 191.0 |

| 4.8 | 52.0 | 86.0 | 10.2 | 87.0 | 133.0 | 18.0 | 130.0 | 191.0 |

| 4.9 | 52.0 | 86.0 | 10.3 | 87.0 | 133.0 | 18.5 | 135.0 | 198.0 |

| 5.0 | 52.0 | 86.0 | 10.4 | 87.0 | 133.0 | 18.8 | 135.0 | 198.0 |

| 5.1 | 52.0 | 86.0 | 10.5 | 87.0 | 133.0 | 19.0 | 135.0 | 198.0 |

| 5.2 | 52.0 | 86.0 | 10.6 | 87.0 | 133.0 | 19.3 | 140.0 | 205.0 |

| 5.3 | 52.0 | 86.0 | 10.7 | 94.0 | 142.0 | 19.5 | 140.0 | 205.0 |

| 5.4 | 57.0 | 93.0 | 10.8 | 94.0 | 142.0 | 19.8 | 140.0 | 205.0 |

| 5.5 | 57.0 | 93.0 | 10.9 | 94.0 | 142.0 | 20.0 | 140.0 | 205.0 |